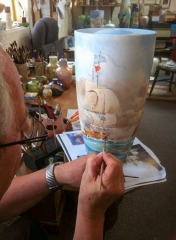

When freehand painting on porcelain and bone china, ground glass metal oxide colours are employed. This process is performed many times and the oxide plus glass is fired and crushed in steel rollers up to ten times to make it fine enough to work with. We then mix this fine powder with fat oil (a substance obtained from pure turpentine) and aniseed oil or clove oil. Once the design has been freehand painted onto the glaze the item is put into the kiln and fired up to 810 degrees Centigrade. This takes about 10 hours allowing time for the kiln to cool. Once the piece is out of the kiln the colours will have faded noticeably into the glaze, this is a first fire.

The second fire is to paint over virtually the whole piece again and strengthen all the colours and add more detail. The piece is fired again and after the second fire, a third layer of colour is added to the main subject to add more detail and depth so it stands out from the background. This process is repeated up to a further four times before a final embellishment of 22 carat gold or platinum and firing at 840 degrees centigrade to complete the process.